In textiles, a stitch is a series of repetitive single turn or loop of

threads or yarns through interloping, intra-looping, or interlacing. It

is the fundamental element for sewing, knitting, embroidery, crochet,

and needle lace-making whether by hand or machine. It can be formed by

any of the following three methods:

- Interloping: It is formed by passing the loop of one thread through the loop of another sewing thread. E.g. Stitch type 401

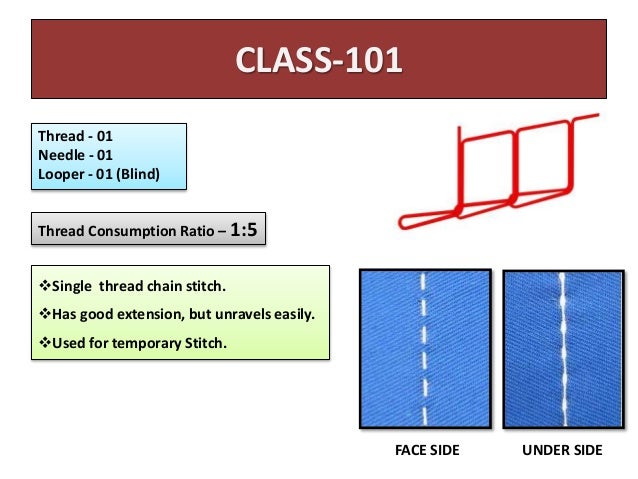

- Intra-looping: It is formed by passing the loop of one thread through the loop of the same thread. E.g. Stitch type 101

- Interlacing: It is formed when one thread passes over another thread. E.g. Stitch type 301

1. Class 100: Single Thread Chain stitch

The stitches formed here are from one or more needle by the method of intralooping. Thus, one or more loops of the needle thread are passed through the fabric and secured by looping with the next loop of the same thread after they are passed through the fabric. This type of stitch is very insecure as each loop is dependent on the next loop and a single thread breakage can pull apart the entire stitch.

2. Class 200: Hand Stitch

These types of stitches are hand stitches that are used for decorative purposes. These are formed by a single sewing thread and the stitch is held by a single line of thread passing from one side to the other side of the fabric. This is mostly used for casual fitting with a simple sewing needle and thread as domestic needs but is also found as topstitch in high-priced garment due to its perfect finish. This can also be done on automatic machines called pick stitch sewing machines but are very slow and are rarely in use. The front and back of all the other types are given below.

3. Class 300: Lock Stitch

Lock stitch is the most common form of stitch in ready-made garments and is formed when the thread or threads are introduced from one side of the material to interlace with thread or threads introduced from the other side of the material. The top thread is called the needle thread and the bottom thread is called the bobbin thread. The interlacing of the threads makes the stitch secure and difficult to unravel makes it the most appropriate for a wide range of seams. Also, lockstitch has adequate strength for most purposes with a correct combination of thread and fabric.The main disadvantages of lock stitch are

- Limited bobbin thread length makes it necessary for changing of the bobbin from when it gets finished.

- Multi-needle stitching with many closed space needles is not possible due to limited space for bobbin. So, at most two needles can be used in a lock stitch machine.

- The interlacing of thread limits the elasticity of the stitch and is unsuitable for edge neatening.

- It is not suitable for knitted fabric due to lack in elasticity.

4.Class 400: Multi-thread Chain Stitch

It is a multi-thread chain stitch type where loops formed in one set of sewing thread is passed through the fabric and are held by interloping and interlacing with loops formed by another set of threads called the looper threads. It looks like that of a lock stitch on the front side of the fabric but has a double chain effect created by the looper thread on the backside. Compares to lock stitch, a 2-thread chain stitch is much stronger and since no threads are interlocking with each other within the fabric there are lesser chances of having a puckering in the seam. Another advantage of this is that both the needle and looper thread runs from large cones on the top of the machine unlike that of the limited sewing thread inside bobbin. Also, it runs much faster than that of a lock stitch machine at 8000rpm.Stitch type 401 is the most common of them all and is used in sewing jeans and trousers and is also used with over lock as a safety stitch. Stitch type 406,407 are used for joining lace, braid, elastics with the garment. The front and back of all the other types are given below.

5. Class 500: Over-edge Chain Stitch

It is mostly known as overlock stitch and is formed by one or more sets of sewing threads with at least one set of thread going around the raw fabric edge. All the stitch in this class has high elasticity which does not unravel on thread breakage. Also, the machines are equipped with a trimming knife to make the edge neat before sewing. The width of the stitch may vary from 3-5mm. Overlock stitches are classified according to the number of threads used for sewing such as 1,2,3,4 or 5 thread stitches. Each of these stitches is different in appearance and their respective benefits are:- 1 thread overlock stitches are used for butt-seaming.

- 2 -3 thread overlock stitches are used as edge neating seam in woven and knitted garments.

- 4 thread overlock stitch also known as mock safety stitch provide extra strength while retaining flexibility.

- 5 thread stitch has two needle threads known as safety stitch which forms stronger seam.

6. Class 600: Covering Chain Stitch

It is mostly known as Flat lock stitch and is formed by three sets of sewing thread namely, needle, looper, and spreader. Apart from the needle threads, the other two sets cover the top and bottom part of the stitch. It is the most complicated of all types with up to a total of nine threads including four needles and rest looper and spreader thread.

Mail:jonytex073@gmail.com

+8801912885383